Why Steel Fixing Melbourne Is Essential for Your Construction Projects

Why Steel Fixing Melbourne Is Essential for Your Construction Projects

Blog Article

Enhance Construction Effectiveness With Specialist Steel Fixing

In the realm of building, the role of expert steel dealing with can not be overstated, as it directly influences both the structural integrity and performance of tasks. Knowledgeable steel fixers use their knowledge to ensure accurate placement and secure tying of supports, which is important in minimizing pricey errors and enhancing material use. Nevertheless, the obstacles encountered in this crucial facet of construction are complex and often neglected. Recognizing these complexities may disclose techniques that might change project end results, triggering a more detailed exam of just how such enhancements can be executed properly.

Relevance of Steel Mending

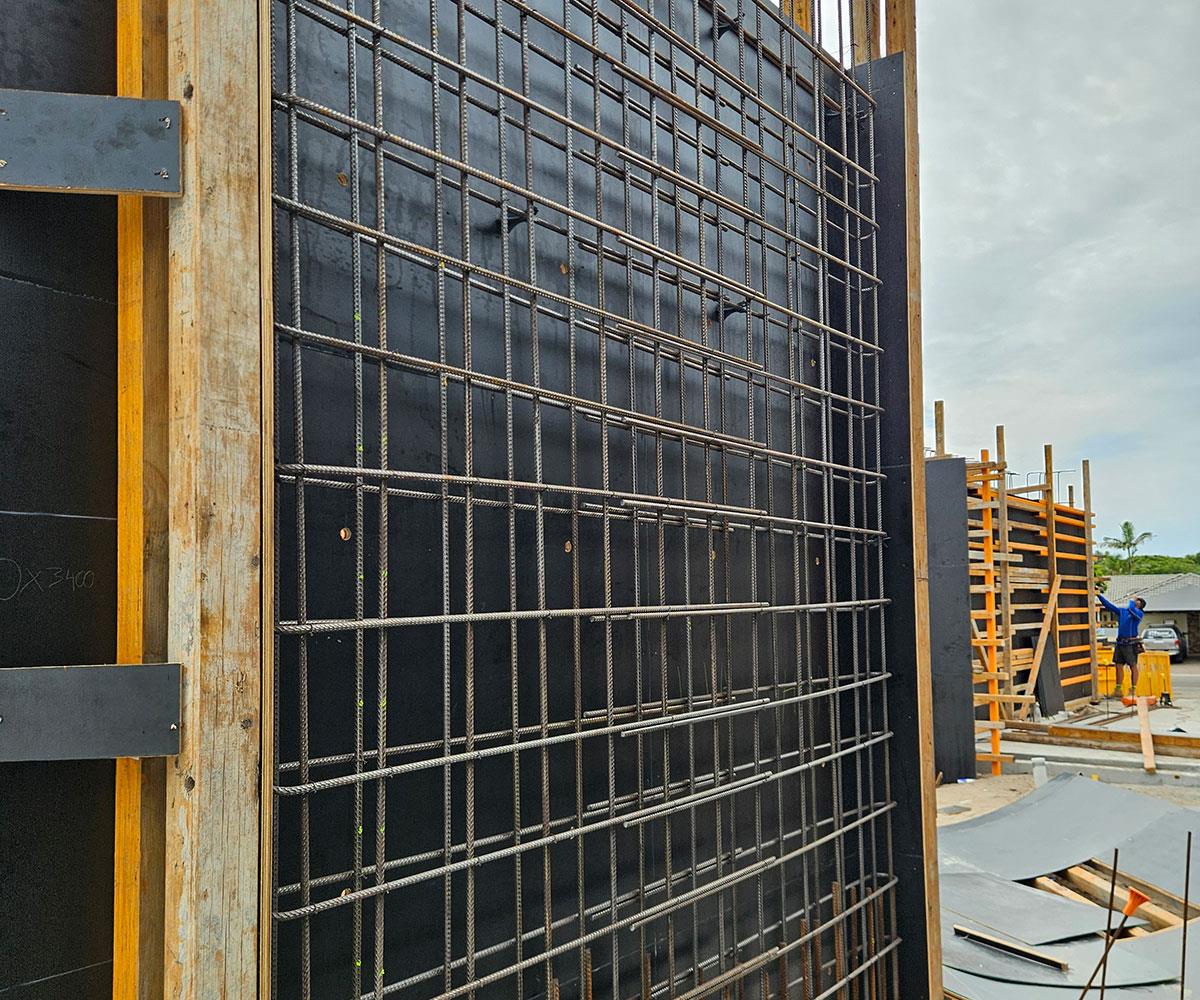

Why is steel taking care of a critical part in building? Steel repairing includes the placement and protecting of steel reinforcement bars (rebars) within concrete frameworks, ensuring architectural honesty and resilience. This procedure is vital in offering tensile stamina to concrete, which naturally lacks this property. Without proper steel taking care of, structures are at danger of failure under different lots, consisting of compression, shear, and tension.

Furthermore, the accuracy associated with steel dealing with straight influences the overall quality of building. Exact positioning of rebars makes certain that styles are followed, minimizing the threat of structural weak points. Steel repairing adds to the efficient transfer of lots within a framework, allowing for the building and construction of much safer and more resistant structures.

In addition to enhancing structural performance, steel dealing with additionally contributes in enhancing building timelines. By ensuring that steel support is correctly positioned prior to concrete is poured, the danger of rework is substantially lowered. This streamlined method not just conserves time but likewise reduces general task costs. Hence, recognizing the relevance of steel repairing is basic for professionals in the building and construction sector, as it forms the foundation of secure and long lasting frameworks.

Advantages of Expert Proficiency

Additionally, experienced steel fixers are adept at translating building and engineering strategies. Proficient steel fixers are trained in industry requirements and finest practices, which aid to alleviate risks connected with steel job.

Furthermore, utilizing expert services can lead to extra effective use of materials. Specialists can optimize the quantity of steel called for, hence reducing material prices and decreasing waste. This efficiency not just profits the budget yet additionally aligns with lasting building practices.

Lastly, counting on specialist knowledge cultivates a collective setting among specialists, designers, and designers, promoting smooth communication and project execution. Generally, the benefits of expert competence in steel dealing with are important, dramatically influencing the success and top quality of building and construction tasks.

Strategies for Efficient Steel Mending

Efficient steel dealing with strategies are important for guaranteeing prompt job completion and optimal structural efficiency. One of the leading methods involves specific preparation and design of rebar positionings based on architectural illustrations. Using sophisticated software application for 3D modeling can help with better visualization and coordination amongst the job group, minimizing mistakes throughout installment.

Furthermore, utilizing suitable securing strategies, such as wire linking or mechanical couplers, can improve joint integrity and lower labor time. Training employees in best methods for security and effectiveness is likewise essential, as experienced workers can perform jobs a lot more promptly and properly.

Last but not least, routine inspections during the installation process can aid recognize and fix potential issues early, stopping expensive hold-ups. By integrating these techniques, building tasks can attain improved efficiency and improved structural quality, ultimately delivering better end results for customers and stakeholders.

Common Obstacles and Solutions

While carrying out effective methods can significantly enhance steel dealing with procedures, numerous obstacles frequently arise that can restrain progress. One usual challenge is the miscommunication in between teams, resulting in errors in steel positioning and boosted rework. To address this, establishing clear communication methods and utilizing advanced software program for sychronisation can improve accuracy and team effort.

An additional considerable problem is the irregularity in website conditions. Unpredicted variables such as weather modifications or ground instability can disrupt steel repairing procedures. A positive solution includes carrying out comprehensive website assessments and having backup plans in place to minimize prospective delays.

Furthermore, labor shortages can original site impede the prompt conclusion of steel taking care of tasks. Purchasing training programs and fostering a society of skill development among employees can assist link this gap.

Last but not least, inadequate safety and security steps can posture risks to both workers and the project timeline. Implementing rigid safety methods and normal training sessions can enhance worker safety and security and decrease accident-related interruptions. By acknowledging these challenges and applying reliable solutions, building and construction specialists can ensure an extra reliable and effective steel dealing with procedure, inevitably bring about successful job outcomes.

Influence on Project Timelines

The influence of steel repairing on job timelines is an important factor to consider for construction professionals. Reliable steel taking care of straight influences the total timetable, as delays in this stage can lead to significant setbacks in succeeding building and construction activities. Correctly carried out steel fixing ensures that the structural stability of the job is accomplished in a timely manner, helping with a smooth transition to the following phases of building and construction.

When steel fixing is executed by knowledgeable professionals, the risk of errors and revamp is lessened, advertising adherence to the planned timeline. Conversely, substandard steel fixing can cause costly delays, needing additional time for evaluations and adjustments. The integration of innovative strategies and technologies in steel fixing, such as 3D modeling and prefabrication, can better improve performance, permitting for quicker setup and decreased labor prices.

Furthermore, timely conclusion of steel repairing effects the scheduling of various other professions, such as concrete completing and putting job. steel fixing. By prioritizing specialist steel dealing with, building teams can successfully manage their timelines, making certain tasks are delivered on schedule and within spending plan. Ultimately, buying top quality steel taking care of services is essential for keeping official site project momentum and achieving successful end results

Final Thought

Finally, specialist steel taking care of plays a vital duty in boosting construction effectiveness by making certain the precise positioning and secure linking of steel reinforcements. The adoption of innovative strategies, such as 3D modeling, streamlines the installment process, reducing errors and remodel. Collaboration amongst specialists, engineers, and designers even more strengthens job outcomes, ultimately adding to the structural honesty and toughness of concrete frameworks. Focusing on professional competence in steel dealing with is vital for the success of building and construction jobs.

Steel check out here repairing entails the positioning and safeguarding of steel reinforcement bars (rebars) within concrete frameworks, making sure architectural stability and resilience. Competent steel fixers are educated in market standards and best techniques, which aid to mitigate dangers linked with steel work.

By recognizing these obstacles and executing effective options, construction professionals can make certain a much more reliable and reputable steel repairing process, ultimately leading to successful project results. (steel fixing)

By focusing on specialist steel dealing with, building teams can properly handle their timelines, making sure projects are supplied on schedule and within budget plan.In verdict, professional steel repairing plays a crucial function in enhancing building and construction effectiveness by guaranteeing the exact positioning and safe linking of steel reinforcements.

Report this page